PFM Crowns

Porcelain Fused to Metal

Porcelain-fused-to-metal (PFM) crowns are dental restorations known for their durability and aesthetic appeal.

PFM crowns need to balance mechanical properties alongside aesthetic and biocompatibility considerations. Optimising factors such as tooth preparation, material quality, design and manufacturing processes can improve the strength metrics, thus enhancing the crown’s longevity and functionality in the oral environment. Regular clinical evaluations and developments in material science continuously contribute to improving EOCA Lab’s PFM crown performance.

In addition, an understanding and analysis of flexural, compressive and tensile strength helps to decide upon the clinical use in your practice.

Factors Influencing Performance of a PFM Crown

Preparation

Proper and adequate tooth preparation is essential to ensure that the PFM crown can properly support the forces it will encounter.

An ideal PFM crown preparation requires adequate tooth reduction for the porcelain and metal layers, smooth, well-defined finishing lines (like a chamfer or shoulder) and rounded, tapered axial walls to ensure retention and proper crown fit. Key details include: 1.2-1.5 mm labial/facial reduction for anterior teeth and 1.5-2 mm occlusal reduction for posterior teeth. Rounded edges and a 5-10 degree taper provide necessary retention for the crown.

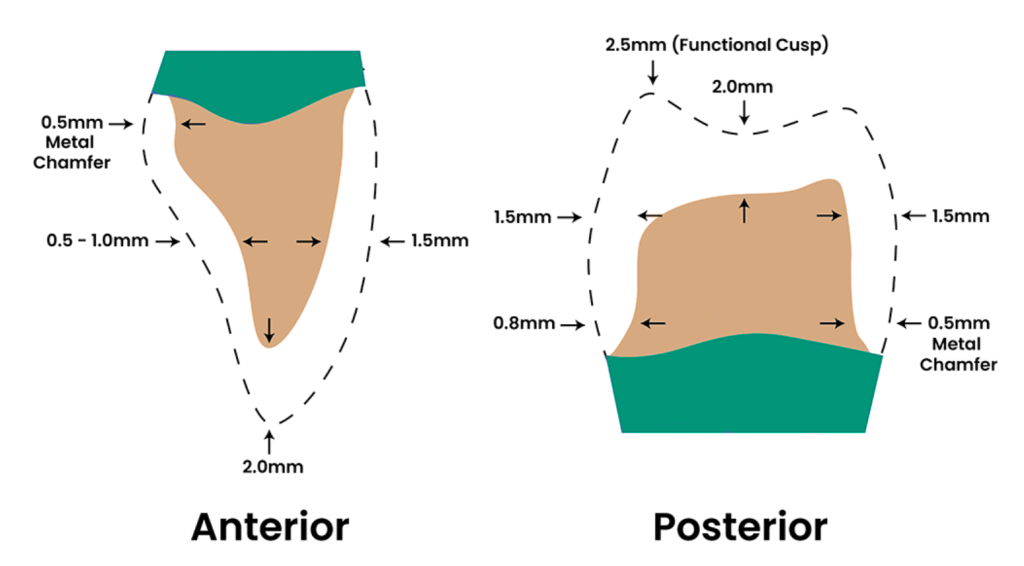

Anterior Preparation:

🔹 0.5mm metal chamfer

🔹 0.5 – 1.0mm axial reduction

🔹 1.5mm incisal reduction

🔹 2.0mm incisal clearance

Posterior Preparation:

🔹 0.5mm metal chamfer

🔹 0.8mm gingival reduction

🔹 1.5mm axial reduction

🔹 2.0mm occlusal reduction

🔹 2.5mm reduction on the functional cusp

Material Composition

The type and quality of porcelain and metal alloy used in PFM crowns can significantly affect the flexural strength.

Both high-nobel alloys and non-precious metals produce ideal flexural strength.

Compressive Strength

The compressive strength of a PFM crown varies, but studies show it can range from approximately 1895 ± 317 N to a range of 800–1200 MPa.

This strength comes from the metal substructure, making PFM crowns robust and suitable for posterior restorations and bridges, where they effectively withstand chewing and biting forces better than some all-ceramic options.

However, the ceramic veneer of a PFM crown is more vulnerable to fracture from shearing forces than compressive forces, and its overall strength depends on factors like material thickness and proper tooth preparation

Flexural Strength

The flexural strength of a material measures its ability to resist deformation under load.

In PFM crowns, it indicates how well the material can withstand bending forces which is critical particularly under heavy occlusal forces.

Typical flexural strength of PFM Crowns: The flexural strength of the porcelain layer is generally around 80-150 MPa, whereas the metal has flexural strength of more than 500 MPa. A well fabricated PFM crown has high fracture resistance due to this synergy, making it suitable for posterior teeth and high load areas.

Manufacturing Process

The sintering temperature and cooling rates of PFM crowns during fabrication can affect the structural integrity of the crown. A meticulous attention to detail by the lab is imperative for clinical success.

Bonding Quality

The bond between the porcelain and metal impacts the distribution of stress across the crown, influencing flexural strength.

Porcelain Thickness

The glass ceramic layer fused to the metal contributes to the overall strength, but it is the most vulnerable component, particularly to shear forces.

Luting Agent

The ideal luting agent for a PFM crown is often a resin-modified glass ionomer (RMGIC), such as 3M™ RelyX™ Luting Plus Cement or GC Fuji PLUS, which provides enhanced bond strength, fluoride release and good handling properties.

Alternatively, a dual-cure resin cement can be used for short clinical crowns or when higher bond strength is required, although this involves more steps with a bonding agent.

The choice ultimately depends on the specific clinical situation, including the crown’s retention form, tooth preparation height and desired clinical performance.

Strength and Aesthetics

PFM crowns offer excellent strength from their metal substructure and natural-looking aesthetics from their porcelain exterior, but can have esthetic limitations at the gingival interface from the underlying metal. This versatile crown type is suitable for most areas of the mouth, especially posterior teeth where durability is crucial, though for higher esthetic demand, all-ceramic options are often preferred.

Meticulous attention to detail

Meticulous attention to detail at our digital lab is essential for creating high-quality, accurately fitting and esthetically pleasing dental restorations and innovative retention devices. This detailed work involves precision in creating digital models and designing restorations, careful material selection, precise shaping, intricate layering for lifelike esthetics and rigorous quality control to ensure proper fit, function and appearance.

Handcrafting ceramic layer

Handcrafting the ceramic layer of PFM crown involves a multi-step process of applying different porcelain types (opaque, dentin, and incisal) onto a pre-fired metal framework to build form, function and aesthetics. The ceramic is applied in layers, with each layer fired in a vacuum or air furnace to bond with the preceding layer, a process called "firing".

PFM framework for implants

A PFM framework for implants refers to a PFM restoration, where a strong metal substructure is used as the internal framework for an implant-supported dental bridge or crown, providing durability and support for a custom-shaded, natural-looking porcelain exterior