Lithium Disilicate Crowns - e.Max

Lithium Disilicate (e.Max) crowns are valued for their superior aesthetics due to its natural translucency and light-reflecting properties, excellent strength and durability that resists chipping and breakage.

While they are not as strong as zirconia, e.Max offers high flexural strength (around 360-500 MPa) for durability in many single-unit restorations and anterior bridges.

Lithium Disilicate has excellent biocompatibility and requires minimal tooth preparation, preserving more natural tooth structure, making it a popular choice for anterior and posterior restorations, veneers, inlays, and onlays.

Factors Influencing Performance of a Lithium Disilicate (e.Max) crown

Preparation

- Occlusal Reduction

- Posterior teeth: 1.5–2.0 mm

- Anterior teeth: 1.0–1.5 mm (facial), 1.5 mm (incisal)

- Use depth grooves and follow natural anatomy—especially in the central fossa and functional cusp areas

- Axial Wall Reduction

- Minimum: 1.0–1.5 mm

- Aim for a 6–10° taper for retention and smooth convergence

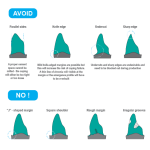

- Avoid undercuts and sharp internal line angles

- Finish Line

- Type: Rounded shoulder or deep chamfer

- Width: 1.0–1.2 mm

- Smooth, continuous margins at or slightly below the gingival crest

- Surface Refinement

- Eliminate sharp edges and irregularities

- Use fine diamond burs to polish margins and internal surfaces

- Gingival retraction cords can help expose margins for accurate scanning or impressions

Why This Matters

-

- Strength: Lithium disilicate needs bulk for flexural strength (~400 MPa)

- Bonding: Smooth surfaces and rounded margins improve adhesive bonding

- Aesthetics: Proper reduction allows for natural translucency and shade matching

Material Composition

- Silicon dioxide (SiO₂) – forms the glassy matrix; provides translucency and enamel-like aesthetics .

- Lithium oxide (Li₂O) – combines with silica to form lithium disilicate crystals (Li₂Si₂O₅), which give the material its strength.

- Phosphorus pentoxide (P₂O₅) – promotes nucleation and crystallization during heat treatment.

- Alumina (Al₂O₃) – enhances mechanical strength and chemical durability.

- Potassium oxide (K₂O) – improves thermo-mechanical properties and stability.

- Zinc oxide (ZnO) and Zirconium dioxide (ZrO₂) – further reinforce the structure and improve wear resistance

- After heat treatment, the material contains ~70% lithium disilicate crystals embedded in a glassy matrix

- These needle-like crystals are responsible for the crown’s flexural strength (~400 MPa) and fracture toughness, while the glassy phase ensures optical brilliance.

- Aesthetics: Mimics natural enamel with lifelike translucency

- Strength: Suitable for both anterior and posterior crowns

- Bonding: Compatible with adhesive cementation for a strong seal

- Biocompatibility: Gentle on gingival tissues and resistant to plaque accumulation

Compressive Strength

-

- Typical Range: Around 315–365 MPa, depending on the core material and fabrication method.

- Pressed vs. Milled: Pressed lithium disilicate tends to show slightly higher compressive strength than milled versions due to its denser microstructure.

- Core Support: Studies show that whether supported by composite or amalgam cores, lithium disilicate crowns maintain similar compressive strength to natural tooth structure.

-

- Strong enough for premolars, molars and anterior crowns

- Best used with adhesive bonding to maximize fracture resistance

- Ideal for esthetic zones where translucency and color matching matter

Flexural Strength

Lithium disilicate crowns, especially those made from IPS e.max or similar materials, are known for their impressive flexural strength, which makes them ideal for both anterior and posterior restorations.

Flexural Strength Overview-

- Lithium disilicate’s strength comes from its high crystalline content (up to 70%), which reinforces the glass matrix and improves load-bearing capacity

- Pressed lithium disilicate tends to outperform milled versions due to denser microstructure and fewer flaws introduced during fabrication

- Typical Range: Around 360–400 MPa for fully crystallized lithium disilicate ceramics.

- Why It Matters: Flexural strength reflects a material’s ability to resist deformation and fracture under load—especially important in areas with lateral or shearing forces

- Comparison: Feldspathic porcelain: ~130–160 MPa, Leucite-reinforced ceramics: ~160–200 MPa, Zirconia: ~900–1200 MPa (much higher, but less translucent)

-

- Suitable for single crowns, veneers, inlays/onlays, and even three-unit bridges in the anterior region

- Best used with adhesive bonding to maximize fracture resistance

- Offers a strong balance of mechanical durability and esthetic translucency

Biaxial Tensile Strength

The term “tensile strength” is not typically used for lithium disilicate IPS e.max dental crowns; instead, their strength is described using biaxial flexural strength values, which indicate their ability to withstand chewing forces and fracture resistance.

Monolithic lithium disilicate material in e.max crowns has a high biaxial flexural strength, ranging from ~360 MPa for IPS e.max CAD to 400 MPa for IPS e.max Press.

Clinical Implications: The high flexural strength of e.max allows for thinner restorations with improved durability and resistance to chipping and wear.

Manufacturing Process

IPS e.max crowns are manufactured from lithium disilicate glass-ceramic through one of two processes: CAD/CAM Milling or Lost-Wax Pressing.

For CAD/CAM, the process starts with a digital impression and designing the crown on a computer, which is then milled from a partially crystallized “blue” block.

For pressing, a wax pattern is invested, burned out, and the molten lithium disilicate is pressed into the cavity at high temperatures.

In both methods, a final heat treatment crystallizes the material, enhancing its strength, followed by shading and glazing to achieve a natural tooth appearance.

Bonding Quality

The quality of bonding for IPS e.max crowns is excellent and relies on an etch-and-bond technique using a silane coupling agent and a resin cement. This adhesive process creates a strong, chemical bond between the lithium disilicate material and the tooth structure, enhancing the restoration’s strength, durability, and long-term success.

Porcelain Thickness

The recommended minimum porcelain thickness can be as low as 1 mm for anterior and posterior teeth, particularly when using adhesive cementation, while minimal thickness restorations like veneers can go down to 0.4 mm, or even lower for occlusal veneers. These thin designs are possible due to the high flexural strength and durability of the lithium disilicate material, which allows for more conservative tooth preparation and preservation of natural tooth structure.

Excellent durability

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Superior esthetics

Meticulous preparation required

Meticulous attention to detail

Meticulous attention to detail at our digital lab is essential for creating high-quality, accurately fitting and esthetically pleasing dental restorations and innovative retention devices. This detailed work involves precision in creating digital models and designing restorations, careful material selection, precise shaping, intricate layering for lifelike esthetics and rigorous quality control to ensure proper fit, function and appearance.