Zirconia Crowns

Zirconia dental crowns are fabricated from zirconium dioxide, a very strong and durable ceramic material that offers a balance of metal-like strength and porcelain-like aesthetics.

They are designed to provide a long-lasting and biocompatible solution with a natural tooth-like appearance and color.

Zirconia crowns can be fabricated from a single, solid block of zirconia or layered with porcelain to achieve higher translucency and a more esthetic look, making them suitable for both anterior and posterior teeth.

FMZ crowns offer excellent strength when a monolithic structure is preferred, especially in the posterior regions. FMZ-T crowns offer improved aesthetics and excellent strength when a monolithic structure is preferred, especially in the anterior regions.

-

Fully Milled (FMZ)

A fully milled zirconia crown, also known as a monolithic zirconia crown, is a dental restoration carved from a single block of zirconia using CAD/CAM (computer-aided design/computer-aided manufacturing) technology. These crowns are favored for their exceptional strength, durability, and biocompatibility, making them ideal for posterior teeth where biting forces are high. Because they are milled from a solid block and not layered with porcelain, they have a higher risk of being opaque and less translucent than other crown types

-

Fully Milled Translucent (FMZ-T)

A fully milled translucent zirconia crown is a high-strength, tooth-colored ceramic restoration that's digitally designed and sculpted by a milling machine from a single, opaque block of Y-TZP (yttria-stabilized tetragonal zirconia polycrystal). It is a monolithic (single-block) restoration, meaning it does not have a layered porcelain veneer, which increases its durability and reduces the risk of chipping. Translucency is a key characteristic, allowing more light to pass through, which enhances its natural appearance, making it suitable for use on both posterior and anterior teeth.

-

Porcelain Fused to Zirconia (PFZ)

A Porcelain Fused to Zirconia (PFZ) crown is a dental restoration with a strong, opaque zirconia substructure (the core) and a more translucent, esthetic porcelain veneer applied on top. This design combines the superior strength and biocompatibility of zirconia, ideal for molars, with the natural tooth-like appearance of porcelain, making it an excellent choice for visible anterior teeth as well.

Factors Influencing Performance of a Zirconia Crown

Preparation

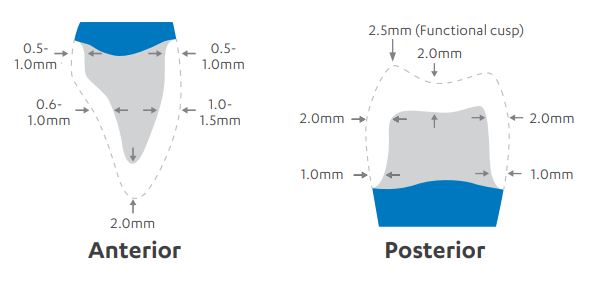

Preparing a tooth for a zirconia crown involves creating sufficient tooth reduction for adequate thickness (0.5-1.5mm), maintaining a tapered preparation angle (4-8 degrees), establishing a continuous circumferential chamfer, rounding all occlusal edges and ensuring no undercuts are present. Key aspects include axial reduction to ensure smooth, convergent walls and occlusal reduction to prevent bite issues, along with a specific margin design, preferably a shoulder or chamfer, to support the strong zirconia material.

Specific Guidelines for Zirconia Crowns

- Wall Thickness: Ensure a minimum wall thickness of 0.5mm, with an ideal of 1mm to 1.5mm for the zirconia to be strong and durable.

- Preparation Angle: Aim for a taper of 4° to 8° on the preparation’s axial walls.

- Margin: A visible and continuous circumferential chamfer or shoulder preparation is crucial.

- Edges: Always round the occlusal edges to enhance strength and fit.

- No Beveling: Beveling is generally not recommended for zirconia preparations.

Material Composition

Zirconia crowns are primarily composed of zirconium dioxide (ZrO₂) a strong, tooth-colored ceramic known for its exceptional strength, durability and biocompatibility. The material can be customized for aesthetic purposes by adding a layer of porcelain or by using different formulations with varying levels of translucency, like Y-TZP (yttria-stabilized tetragonal zirconia polycrystal) or PSZ (partially stabilized zirconia), to match natural teeth more closely

Compressive Strength

The compressive strength of zirconia dental crowns typically ranges from 600 to over 1200 MPa, but this can vary significantly depending on the specific type of zirconia (e.g., high-strength vs. ultra-translucent). Factors such as composition, processing and aging resistance also influence a crowns’ overall strength. While high compressive strength makes zirconia excellent for resisting biting forces, its fracture resistance to tensile or shear forces is lower and its durability can be affected by the environment and the way it’s used.

Flexural Strength

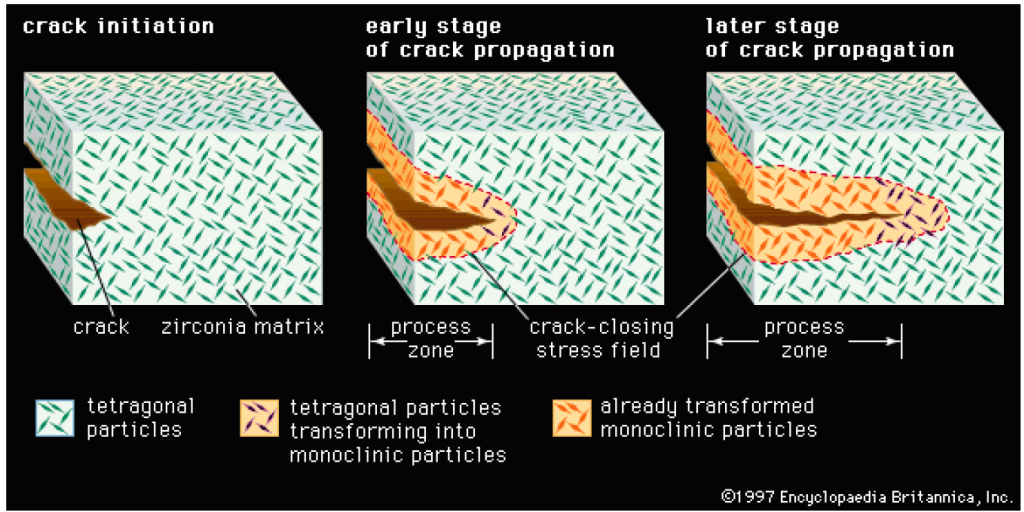

The flexural strength of zirconia crowns is exceptional due to its ability to resist bending and fracturing under the forces of mastication, typically ranging from 900 to 1200 MPa. This high mechanical strength makes zirconia a highly durable and reliable material for restorations, ensuring longevity and resistance to chipping or breakage, especially in the posterior region, due to its ability to undergo a transformation toughening mechanism. Transformation toughening in zirconia crowns relies on the controlled tetragonal-to-monoclinic phase transformation of its crystalline structure under stress, which absorbs energy and expands, thereby inhibiting crack propagation and increasing the material’s overall fracture toughness and strength, similar to the behavior of steel in advanced structural ceramics.

Image Ref: Website Name: Encyclopedia Britannica, Publisher: Encyclopedia Britannica, URL: https://www.britannica.com/technology/advanced-structural-ceramics#/media/1/6681/266, Access Date: 16 September 2025

Tensile Strength

Zirconia crowns do not have high tensile strength values, they typically range from 115 to 711 MPa.

A “low” tensile strength doesn’t mean they are generally weak, but rather that the material can be susceptible to fracture from tensile stresses. Implications include increased risk of chipping and bulk fracture, especially with surface damage (especially after occlusal adjustment) or hydrothermal aging (low-temperature degradation) which can lead to microcracks and loss of strength. This can reduce the longevity of the restoration and lead to premature failure under occlusal loads, though this is often managed by designing restorations to withstand compressive forces, which zirconia excels at.

Manufacturing Process

Zirconia crown manufacturing involves digital design (CAD) and milling (CAM) from a zirconia block, followed by high-temperature sintering to achieve density and strength. Post-sintering, the crown can be shaded, stained, and glazed to match natural teeth and achieve a lifelike appearance. The process concludes with luting the crown to the prepared tooth using resin cement.

Bonding Quality

The “bonding quality” of a zirconia crown refers to the strength and durability of the cement that holds the crown to the tooth, which is a critical factor for long-term success, especially for resin-bonded restorations like veneers and inlays. Achieving a strong bond requires specific surface treatments, such as airborne-particle abrasion (e.g., with aluminum oxide powder) and the use of a phosphate monomer-containing resin cement (which contains MDP), to create a durable chemical bond with the zirconia’s surface. Factors like contamination, inappropriate materials (e.g., certain liner materials), and improper surface treatment can negatively impact bond strength.

At EOCA Lab we offer an enhanced bonding solution, which is a specialized glass-ceramic coating applied to the surface of the zirconia crown to improve its bonding strength, durability, and aesthetic qualities. This technique involves a spray deposition of lithium disilicate (LD), process that creates a thin, uniform layer on the zirconia, mimicking its surface properties. The spray application is a novel technique for enhancing the bond between the zirconia core and a lithium disilicate veneer, creating a stronger, more durable final restoration.

..creates a rough, porous surface after acid etching, improving the surface area for bonding and adhesion. This surface modification maximizes the effectiveness of bonding agents, providing stronger, more reliable adhesion for dental restorations, enhancing the overall dental treatment.

Porcelain Thickness

For zirconia crowns with porcelain layering, the zirconia core thickness is typically 0.3-1.0 mm, and the porcelain veneer thickness is generally 0.3-3.0 mm, depending on the specific design and anatomical area. The total thickness of the final crown, including both materials, needs to be sufficient to cover the prepared tooth structure, aiming for around 1.0 to 1.5 mm of total thickness to ensure adequate strength and esthetics.

Strength and Aesthetics

EDIT PFM crowns offer excellent strength from their metal substructure and natural-looking aesthetics from their porcelain exterior, but can have esthetic limitations at the gingival interface from the underlying metal. This versatile crown type is suitable for most areas of the mouth, especially posterior teeth where durability is crucial, though for higher esthetic demand, all-ceramic options are often preferred.

Meticulous attention to detail

Meticulous attention to detail at our digital lab is essential for creating high-quality, accurately fitting and esthetically pleasing dental restorations and innovative retention devices. This detailed work involves precision in creating digital models and designing restorations, careful material selection, precise shaping, intricate layering for lifelike esthetics and rigorous quality control to ensure proper fit, function and appearance.

Handcrafting ceramic layer

EDIT Handcrafting the ceramic layer of PFM crown involves a multi-step process of applying different porcelain types (opaque, dentin, and incisal) onto a pre-fired metal framework to build form, function and aesthetics. The ceramic is applied in layers, with each layer fired in a vacuum or air furnace to bond with the preceding layer, a process called "firing".

xxx

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.